If your answer is no, or what is that? – Then we’re glad you’re here.

There is no doubt that despite the impacts brought on by the pandemic, demand for manufactured goods has not just increased, but the rate and cost at which items are produced have increased as well. While this occurrence may seem odd given the negative impact of the pandemic on production overall, the need to deliver more outputs at higher speeds, at significantly lower costs has only added to the already high pressure of producing materials.

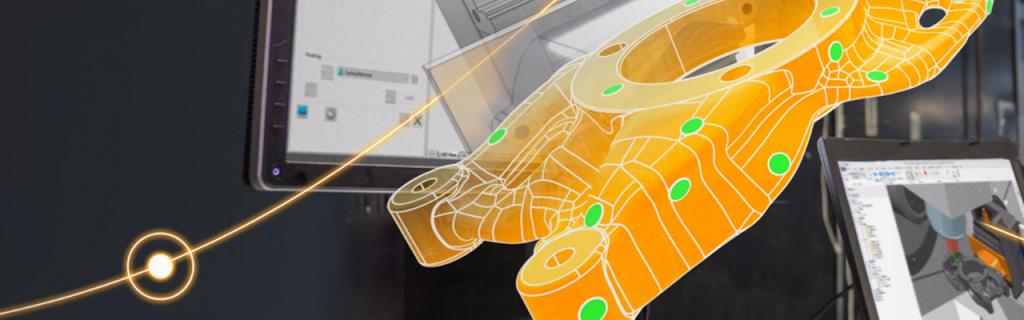

Luckily, technology remains at the forefront of development in the manufacturing disciplines, and over the next few weeks, we will be breaking down 4 key drivers that you can adopt or implement in your organisations to better prepare yourself for Industry 4.0. These are, moving from 2D to 3D Design, Design Automation, Simulation, and Generative Design – with Data Management at the core of these stages.

Before we dive deeper into these, let reflect on the past 3 industrial revolutions’ key impacts on manufacturing:

First Industry Revolution: was started in the 18th century. During this manual tasks were replaced by the use of steam engines and other machines. The agriculture and textile industries benefited most from the first industrial revolution.

Second Industrial Revolution: Starting at the end of the 19th century and picking up momentum in the 20th century, the second industrial revolution saw the introduction of steel and the usage of electricity within factories. Productivity saw a big increase and bringing mass production into the forefront.

Third Industrial Revolution: started in the middle of the 20th century, meaning that most of today’s factories are the product of this revolution. During this time manufacturers started to incorporate electronics, digital technology, and automation inside the factory – speeding up processes and accelerating time to market more than ever before.

Fourth Industrial Revolution: Welcome to Industry 4.0! In advanced factories, automated machines and robots are aiding the human workforce to do manufacturing activities. But this is just a start. Industry 4.0 will take manufacturing to a new level by introducing the concept of smart factories, producing smart products using flexible mass manufacturing technologies. Inside smart fully automated factories machines will operate independently.

Industry 4.0 signifies the promise of a new Industrial Revolution, one that marries advanced production and operations techniques with smart digital technologies to create a digital enterprise that would not only be interconnected and autonomous but could communicate, analyse, and use data to drive further intelligent action back in the physical world.

It represents how smart, connected technology would become embedded within organizations, people, and assets, and is marked by the emergence of capabilities such as robotics, analytics, artificial intelligence, and cognitive technologies, nanotechnology, quantum computing, wearables, the Internet of Things, additive manufacturing, and advanced materials. In short, Industry 4.0 ushers in a digital reality that may alter the rules of production, operations, workforce, and even society.

Ready to know and see more? Then connect with us and let’s guide you on your journey to Industry 4.0! Our team of specialist technical consultants are ready to kickstart your digital transformation.

Written By Andile Sikhakhane

0 Comments