In today’s manufacturing world, businesses face many challenges that slow productivity, affect quality, and reduce profits. From delays in production and machine downtime to inefficient workflows and pressure from competitors, manufacturers need better ways to stay competitive. The good news is that automation and connected workflows are changing the game. This blog will look at manufacturers’ main challenges and how modern tools like Fusion workflows and Manufacturing Execution Systems (MES) can help.

The Challenges Manufacturers Face

Manufacturers today deal with several issues that make it hard to run smoothly. Some of the biggest challenges include:

- Delays and Quality Problems:

Delays in production and inconsistent quality are common. These problems often come from inefficient workflows, poor machine maintenance, and a lack of real-time data to monitor processes. - Pressure from Customers and Competitors:

Customers want better quality products, while competitors offer high-quality goods at lower prices, especially abroad. This puts pressure on manufacturers to improve or risk losing business. - Inefficient Workflows:

Traditional workflows often involve separate departments that don’t communicate well. This leads to delays, errors, and wasted time. - Bottlenecks and Machine Downtime:

Bottlenecks – where production slows down – limit the amount that can be produced. Machine downtime worsens things, whether for maintenance, breakdowns, or upgrades. Without good data, it’s hard to find and fix these problems. - Costs of Inefficiency:

Inefficient processes lead to lower profits, poor machine performance, inconsistent quality, and more waste. These issues increase costs and harm a company’s reputation.

The Solution: Connected Workflows and Automation

Manufacturers are turning to connected workflows and automation tools to tackle these challenges. These solutions smooth processes, improve efficiency and provide real-time data to help make better decisions.

1. Fusion Workflow: Linking Design and Manufacturing

The Fusion workflow connects design and manufacturing processes, making changes easier and reducing delays. Key benefits include:

- Quick Updates: Changes in design are automatically updated in the manufacturing process, saving time and reducing errors.

- Less Programming Time: Automation tools cut down the time needed for programming, helping manufacturers adapt quickly to changes.

- Better Efficiency: By removing manual steps and improving communication, the Fusion workflow boosts productivity.

2. Fusion Extensions: Adding Advanced Features

Fusion offers extensions that add more features, such as:

- Manufacturing Extension: Tools for multi-axis machining, advanced nesting, and sheet-based fabrication.

- Simulation Extension: Tools for testing designs, like finite element analysis and injection moulding simulation.

- Design Extension: Features for creating complex shapes, like hole patterns and 3D lattices.

- Manage Extension: Tools for managing changes, releases, and part numbering.

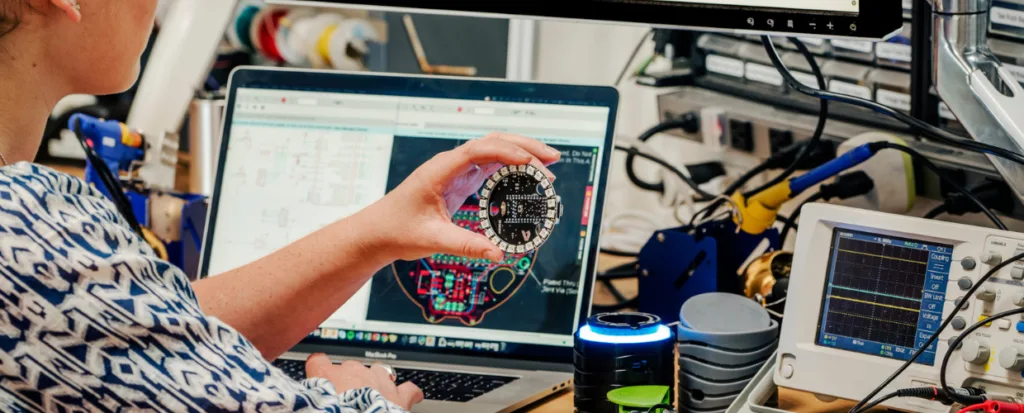

- Signal Integrity Extension: Tools for improving PCB design and testing components.

These extensions help manufacturers handle complex tasks and improve product quality.

3. Tracking and Traceability: Meeting Standards and Improving Efficiency

In today’s regulated environment, tracking and traceability are essential. Connected workflows provide:

- Real-Time Data: Seamless communication between departments improves efficiency.

- Regulatory Compliance: Tracking tools help manufacturers meet standards and improve supply chain transparency.

- Faster Product Recalls: Quick identification of issues reduces costs and risks.

- Better Decision-Making: Clear data helps managers make informed decisions about efficiency, machinery, and training.

- Risk Management: Identifying and fixing risks, like bottlenecks and quality issues, keeps operations running smoothly.

4. Fusion Operations: A Cloud-Based MES for Modern Manufacturing

Autodesk’s Fusion Operations software is a cloud-based Manufacturing Execution System (MES) that works with Product Data Management (PDM) and Product Lifecycle Management (PLM) systems. Key features include:

- Process Flow Control: Managing each stage of production to ensure efficiency.

- Quality Control: Tools to ensure products meet standards.

- Live View: Real-time data from the factory floor to quickly spot and fix issues.

- Production Order Tracking: Replacing paper job cards with electronic tracking to reduce errors and improve efficiency.

Using an MES brings clear benefits: better efficiency, lowered costs, improved inventory control, and more sustainable production.

The Way Forward: Embracing Digital Tools

The challenges manufacturers face are big, but they can be overcome. Businesses can improve efficiency, quality, and profits by using connected workflows, automation, and tools like Fusion and MES.

The key to success is taking a complete approach to digital transformation. This includes:

- Choosing the Right Tools: Solutions like Fusion workflows and MES provide the foundation for efficient operations.

- Training Teams: Teaching employees to use new tools ensures a smooth transition and maximises the investment.

- Continuous Improvement: Regularly reviewing data and processes to find areas for improvement.

Download our FREE eBook today and explore Autodesk’s comprehensive water infrastructure solutions, addressing global challenges through innovative design, simulation, and asset management tools for sustainable water systems.

Conclusion

The manufacturing industry is changing. Traditional workflows and disconnected processes are no longer enough to meet today’s demands. Manufacturers can solve challenges, improve efficiency, and stay competitive in a global market by adopting connected workflows, automation, and modern tools.

The future of manufacturing is digital – are you ready to take the next step?

0 Comments