Revolutionising Intralogistics Design: How LFD Leveraged Autodesk Revit for Unparalleled Efficiency and Precision

Logistics Facility Design (LFD), a trailblazer in the field of intralogistics solutions, has established itself as a leader in designing client bespoke material handling and storage systems for warehouses and other specialised facilities. LFD’s team, comprising seasoned professionals with decades of experience, has consistently delivered innovative solutions across the globe. Their commitment to excellence is exemplified by their strategic adoption of Autodesk Revit, supported by Baker Baynes, which has significantly enhanced their design capabilities, ensuring precision, efficiency, and customer satisfaction.

Customer Challenges:

LFD’s journey to becoming a top player in intralogistics was not without challenges. As a company focused on designing the critical internal systems that make warehouses and other facilities function seamlessly, LFD needed a tool that could bring their complex ideas to life. Initially, they relied heavily on AutoCAD for 2D designs. However, as the industry evolved towards 3D modelling, LFD found themselves at a crossroads. Their existing tools were becoming insufficient for the increasingly complex demands of projects, particularly in creating highly accurate designs that could be easily visualised by all stakeholders. The need to transition to a more advanced design platform became evident, and the company faced the daunting task of implementing a new system while maintaining their reputation for precision and reliability.

Project Goals:

LFD set out with clear goals in mind: to enhance their design capabilities by transitioning from AutoCAD to Autodesk Revit, enabling them to create detailed 3D models that could streamline the design process and improve communication with clients. They aimed to reduce design time, increase accuracy, and leverage the collaborative features of Revit to work more effectively with architects and engineers on large-scale projects. Another critical goal was to ensure that this transition would not only meet current industry standards but also position LFD as pioneers in the use of advanced technology in intralogistics design.

Design Solutions:

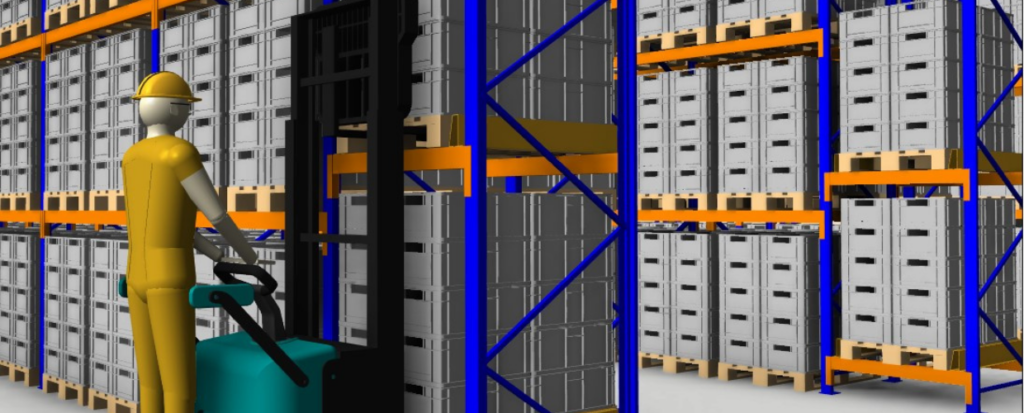

The shift from AutoCAD to Autodesk Revit was a significant leap for LFD. With support from Baker Baynes, the transition was smooth and strategic. Baker Baynes provided essential training and ongoing support, ensuring that LFD’s team quickly became proficient in using Revit. The results were immediate and impactful. Revit’s ability to create comprehensive 3D models allowed LFD to visualise designs with unprecedented clarity. The software’s robust tools enabled the team to develop detailed designs that integrated seamlessly with the broader architectural and engineering plans.

One of the standout features of Revit for LFD was the creation of extensive libraries of families, which streamlined the design process.

“We realised that we were going to stay behind if we didn’t follow the industry trend towards 3D modelling,” says Etienne van Biljon, Design Executive at LFD. “Revit allowed us to not only catch up but to excel by giving us the tools to create detailed, accurate designs efficiently.”

Business Benefits:

The implementation of Autodesk Revit, backed by Baker Baynes’ expertise, has led to substantial business benefits for LFD. The transition has resulted in a 30-40% time saving on design projects, particularly in the revision stages where changes can be implemented quickly across all views. This efficiency gain has translated into cost savings and faster project turnaround times, which are critical in maintaining LFD’s competitive edge.

Revit’s 3D modelling capabilities have also significantly improved client engagement. “The visualisation that Revit provides makes it possible for our clients to understand exactly what we envision,” says Rocco van Vuuren, Director for Logistics Facility Design. “This has led to quicker buy-ins from clients and reduced the need for multiple explanatory meetings, which saves time and builds trust.”

Additionally, LFD’s ability to collaborate more effectively with other professionals, such as architects and engineers, has been greatly enhanced. The detailed and precise models created in Revit ensure that all parties are on the same page, reducing the likelihood of errors and ensuring that projects are completed on time and within budget.

Conclusion:

LFD’s successful transition to Autodesk Revit, with the support of Baker Baynes, has not only enhanced their design process but has also solidified their position as leaders in the intralogistics industry. The combination of cutting-edge technology and expert training has enabled LFD to deliver superior solutions to their clients, ensuring that they remain at the forefront of industry innovation. As LFD continues to expand its global footprint, their partnership with Baker Baynes and the use of Autodesk Revit will undoubtedly play a crucial role in their ongoing success.

0 Comments