Autodesk

AUTODESK FUSION MAKER DESIGN COMPETITION

Show off your Design Skill and Stand the Chance to WIN BIG!

ENTRIES CLOSE : 16 SEPTEMBER 2024

The Autodesk Fusion Maker Design Competition: An Innovation in Portable Power Design Comes to a Close

The Autodesk Fusion Maker Design Competition challenged participants to create a sustainable, efficient portable power pack weighing under 10 kg, with a 100 amp-hour capacity, 1.2 kW output, and 6-hour runtime. Competitors used Autodesk Fusion’s versatile toolset to bring designs to life, incorporating eco-friendly materials, multiple outlets, and user-friendly displays. Judged on functionality, aesthetics, manufacturability, and sustainability, the event drew diverse talent, from seasoned designers to Fusion newcomers. The competition showcased Autodesk Fusion’s capability to enable impactful, sustainable innovation, leaving a lasting mark on the industry and inspiring creative possibilities for portable power solutions.

Imagine designing a portable power pack that redefines convenience and innovation. Your challenge is to create a functional, aesthetically pleasing, durable, and sustainable device. It should have a compact form factor, a 6-hour runtime, 100 amp-hours capacity, 1.2 kW output, and weigh no more than 10 kg. Key features include multiple outlets, a user-friendly display, and an eco-friendly design using sustainable materials. This power station should be able to charge a phone, router, and laptop.

Announcing the Winner of the Autodesk Fusion Maker Design Competition!

We are excited to announce Marina Johnson as the winner of the highly anticipated 2024 Autodesk Fusion Maker Design Competition. Hailing from Tabazimbi, South Africa, Marina’s journey to the top is nothing short of inspiring. A first-time Autodesk Fusion user, Marina took on the challenge of designing a portable power station, impressing the judges with her creative and functional approach. Her design stood out for its sleek aesthetics, thoughtful component placement, and effective use of Autodesk Fusion features.

The competition, aimed at showcasing the versatility of Autodesk Fusion in manufacturing and product design, brought together a range of talented makers and designers. The judging panel, which included Daneel Ballaram, Sahil Shivanand, Henry Levine, and Dr. Andrew Dickson, praised Marina’s design for its manufacturability and practical features. Sahil, one of the judges, remarked, “Marina’s design ticked all the boxes—it’s strong, durable, and aesthetically pleasing, all while being incredibly functional for a first-time user.”

Marina’s win marks the beginning of a new chapter in her life. Along with receiving a high-spec laptop and specialised Autodesk Fusion training, she will have the opportunity to see her design brought to life at a special event in Johannesburg later this year.

Click below to read more about Marina’s story, her innovative design, and how this competition is opening exciting new doors for her future.

The Portable Power Station Design Brief

Design a convenient, on-the-go power station to charge a variety of devices and appliances. Welcome to a detailed overview of what your design submission for the Autodesk Fusion Maker Design Competition should encompass. This competition challenges you to harness the full capabilities of Autodesk Fusion and its extensions to create a revolutionary portable power pack. Your design will be assessed across multiple dimensions that are critical in the world of manufacturing design. Here’s what you need to know and incorporate into your project:

Each component of your submission will contribute to a holistic evaluation of your skills and your design’s potential market success. Make sure your design is not just a concept, but a viable, market-ready product that stands out for its innovation, practicality, and sustainability. Good luck!

Requirements

Function

Your design must deliver on its core promise: efficiency and utility. Ensure the power pack has a 6-hour runtime (should charge a phone, router & laptop), 100 amp-hours, 300 – 700 W output, and a user-friendly interface including multiple outlets/ports and an input charger plug clearly demonstrate these functionalities through practical application in the Autodesk Fusion environment

Aesthetics

Visual appeal is crucial. The design should not only function well but also have a modern, sleek look that appeals to consumers. Use Autodesk Fusion’s Render Workspace to create high-fidelity visuals that showcase your design in the best light, paying attention to form, colour, and overall presentation.

Manufacturability

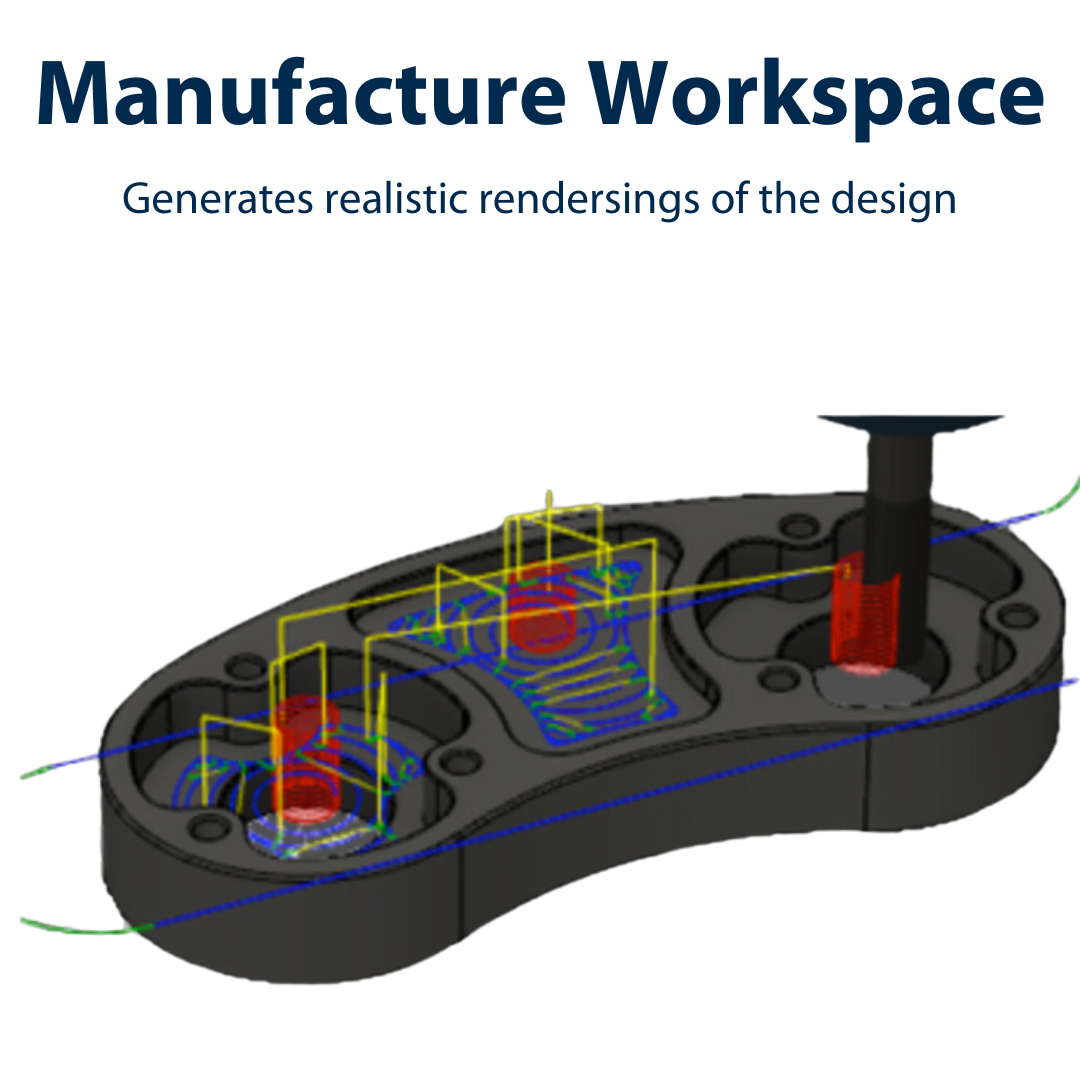

Consider the ease of manufacturing your design. Utilise the Manufacture Workspace to simulate 3D printing and CAM tool path of components. Your design should be feasible for production at a reasonable cost and complexity. Include considerations for assembly, disassembly, and part consolidation to optimise manufacturing processes.

Manufacturing techniques.

1. 3D Resin Printing

2. 2.5 and 3D Machining

3. Vacuum forming.

4. Sheet metal

5. Metal work

No other manufacturing practice will be accepted as an eligible entry

Design

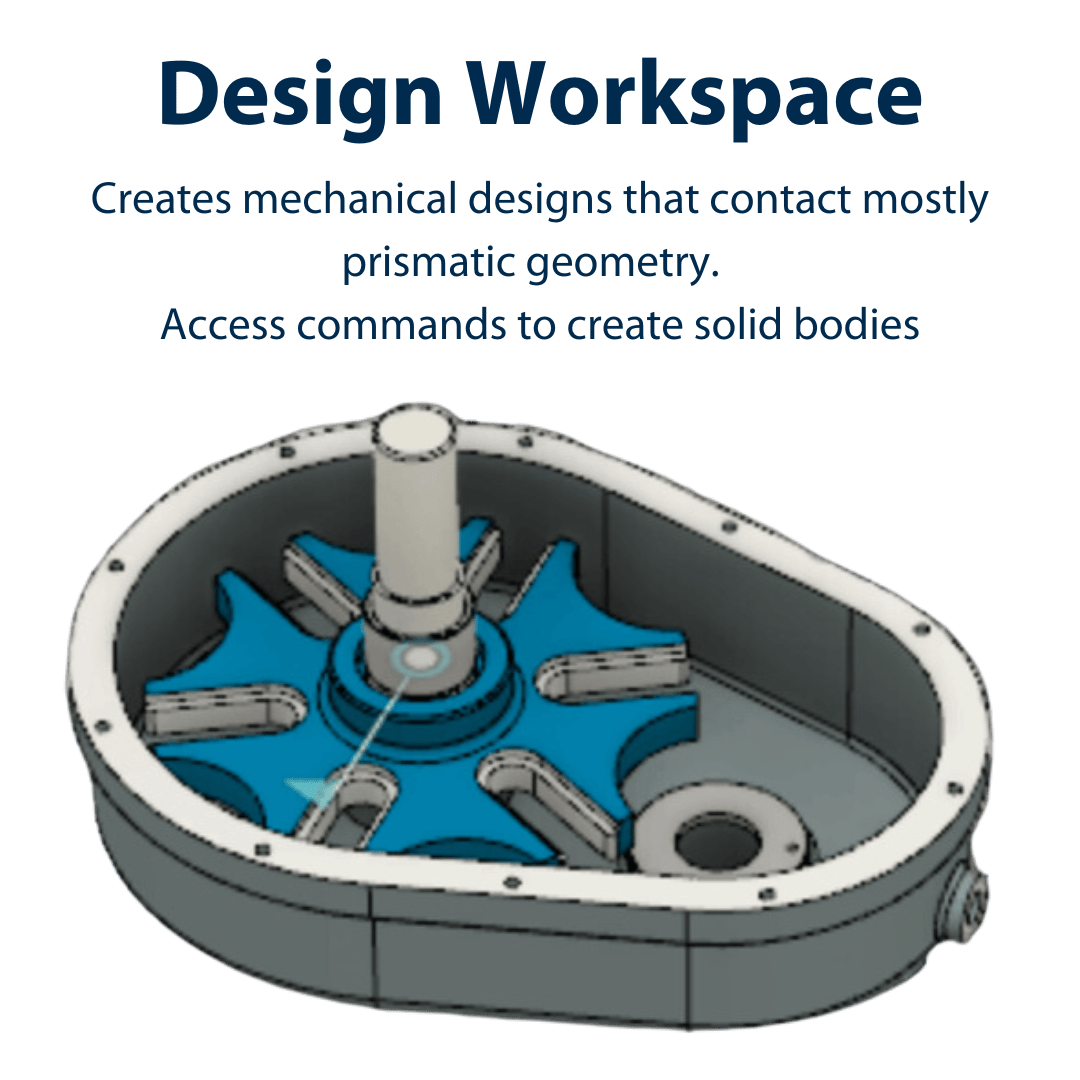

Your initial design sketches and developments should be carried out in Fusion’s Design Workspace. This phase is where creativity meets functionality. Ensure that every feature is planned and accounted for, from dimensions to the integration of electrical components. Produce detailed 2D drawings of your exploded assembly in the Drawing Workspace. This should include all necessary specifications and annotations that would be needed for manufacturing. Accurate and clear drawings are crucial for communicating your design intent to stakeholders and manufacturers.

Animation

Utilise the Animation Workspace to create an exploded view animation of your power pack. This will help in demonstrating how the product is assembled and disassembled, offering clear insights into the design and functionality.

Analysis

Conduct a comprehensive analysis using the Simulation Workspace. Create thermal studies and other simulations to predict real-world behaviours. Analysing your design under theoretical conditions is crucial for validating the functional and durability aspects.

Sustainability/Materials

Casing + Manufacturing Process

Your design must utilise sustainable materials and environmentally friendly manufacturing processes. Reflect this commitment in your choice of materials and design techniques. Consider lifecycle impacts, recycling potential, and the energy required for manufacturing.

Each component of your submission will contribute to a holistic evaluation of your skills and your design’s potential marketsuccess. Make sure your design is not just a concept, but a viable, market-ready product that stands out for its innovation,practicality, and sustainability. Good luck!

Specifications

- 6 Hour Run Time – to charge a phone, router, laptop

100 Amp hours - 300W – 700W Output

- Carry Handle

- Battery Cell Dimensions: 40mm X 130mm X 200mm (Width X Length X Height) Autodesk Fusion files for these components will be placed in your Submission Folder, which will be accessible once your registration is complete.

- Inverter Dimensions: 200mm X 150mm X 100mm (Width X Length X Height) Autodesk Fusion files for these components will be placed in your Submission Folder, which will be accessible once your registration is complete.

- Maximum Housing Dimensions:300mm X 350mm X 250mm (Width X Length X Height)

- Display Screen

- Loading System

- Must be manufactured using sustainable materials

- Light weight – 10Kg Maximum

- Multiple outlets/ports: AC Outlet, USB Port

- Input charger plug

- Manufacturing techniques.

1. 3D Resin Printing

2. 2.5 and 3D Machining

3. Vacuum forming.

4. Sheet metal

5. Metal work

No other manufacturing practice will be accepted as an eligible entry

- Function 30 Points

- Aesthetics: 20 Points

- Manufacturability (DFM) – 20 Points

- Durability – 15 Points

- Sustainability/Materials – Casing + Manufacturing Process – 15 Points

- Fusion Application – META Data – (Total 100 Points)

- Render – 20 Points

- Design – 20 Points

- Drawing – 20 Points

- Animation – 20 Points

- Analysis – 20 Points

Competition Collaborators

Important Resources

3D Model & Assembly Created in Autodesk Fusion’s Design Workspace:

*Available in the 30 Day Trial

AUTODESK Fusion

30-day free Trial

Animation of Exploded View in the Animation Workspace:

*Available in the 30 Day Trial

AUTODESK Fusion

30-day free Trial

3D Print Simulation and CAM Toolpath Simulation of Manufactured Components in the Manufacture Workspace:

*Available in the 30 Day Trial

AUTODESK Fusion

30-day free Trial

Create a thermal study in the Simulation Workspace:

*Available in the 14 Day Trial

AUTODESK Fusion 360 Simulation Extension

14-day free Trial

Create a life like render in the render workspace:

*Available in the 14 Day Trial

AUTODESK Fusion 360 Simulation Extension

14-day free Trial

Links & Requirements

System requirements for Autodesk Fusion

Introduction to Fusion & Overview

Get Started Overview

Introduction to 3D Design and modelling

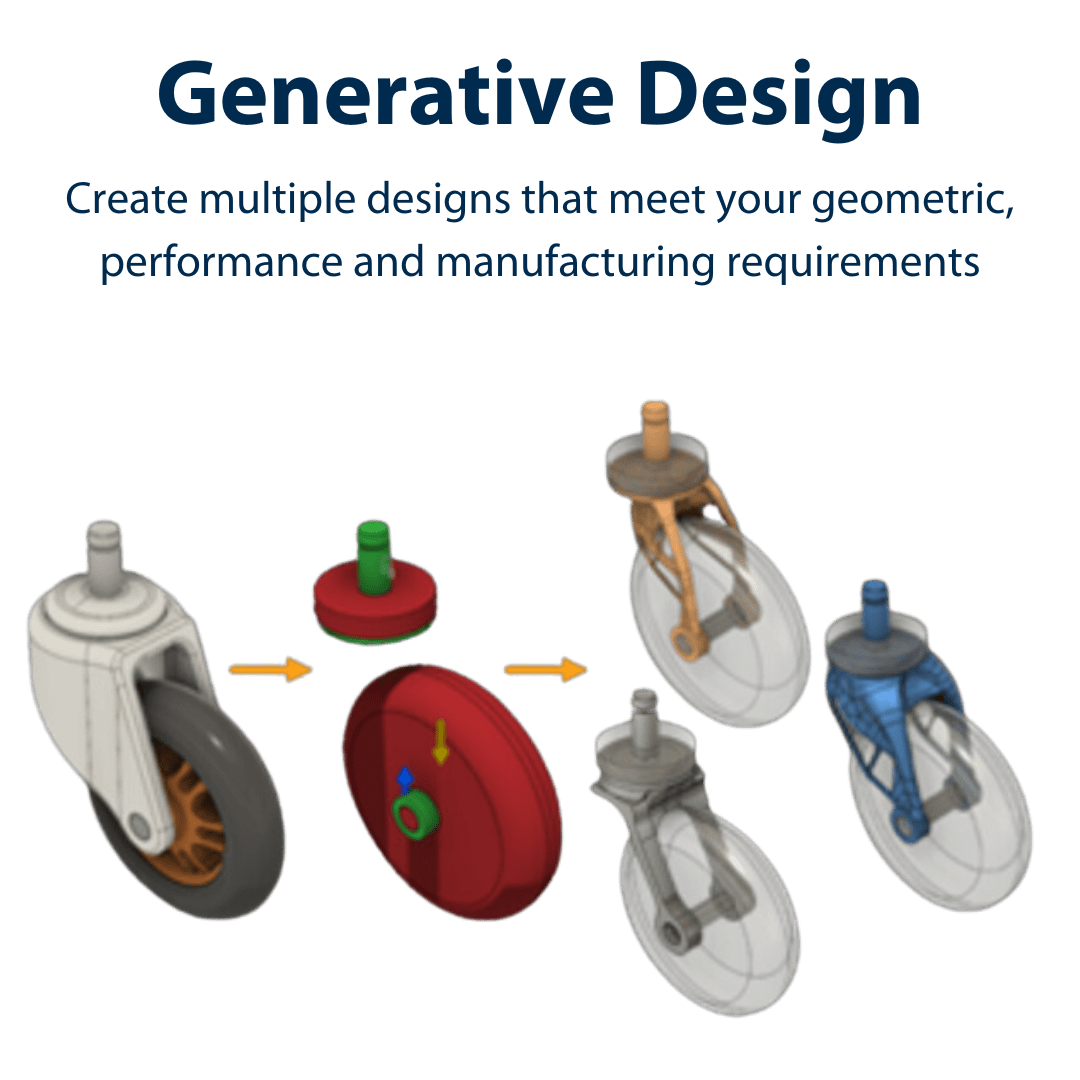

Manufacturing, Electrical, Additive Manufacturing, Generative Design, Simulation and Documentation (2D Drawing)

Free Ebooks

Check out these free Ebooks to help you!

From 2D to 3D: Unveiling the Power of Autodesk Fusion in Design & Manufacturing

Unlock the potential of Autodesk Fusion with ‘From 2D to 3D.’ Explore versatile 3D CAD, integrated CAD/CAM, PCB design, and seamless simulations. Design, machine, and innovate efficiently with this comprehensive eBook

Fusion 360: Design to Machining

Unlock the secrets of seamless design to machining with the “Fusion 360: From Design to Machining” eBook. Master Fusion 360’s powerful tools and workflows, optimising your designs for precision manufacturing. Download your copy now and bring your ideas to life.

Competition Judges

Daneel Ballaram

Key Account Manager Manufacturing | Process, Energy & Mining

Daneel has been involved in helping companies in Manufacturing, Process, Energy, and Mining Industries, digitally transform for the past 12 years. His involvement in Manufacturing businesses spans over 18 years.

Daneel has a rare hybrid skill set of understanding technical and business contexts.

Using his consulting experience and Mechanical Engineering qualifications, Daneel hones deep into customer problems, by understanding each business’s unique context. His client-centric approach involves assessing their current state, strategic imperatives, and market trends before formulating a solution that is aligned with Industry 4.0 best practices.

Being an accomplished Autodesk University Africa speaker, professional trainer, and Autodesk Certified Professional in Manufacturing & Data Management, Daneel is well versed in practical and theoretical foundations to offer the best solutions available.

Dr Andrew Dickson

Engineering Executive at CBI-electric: low voltage

Dr. Andrew Dickson is the Engineering Executive at CBI-electric: low voltage, leading R&D in electrical safety, energy monitoring, and control devices. He also oversees an accredited test facility for product performance and conformance. With over 20 years in the industry and 10 years in his current role, he has extensive design and manufacturing experience. Passionate about education, Dr. Dickson has spent over 25 years in academia, mentoring and lecturing in engineering. He holds a BSc (Eng), MSc (Eng), and PhD from the University of the Witwatersrand and completed the Management Development Programme at the Gordon Institute of Business Science. He is active in SABS technical committees, advocating for strict regulations and product governance.

Melike Ozdemir

Technical Sales Specialist at Autodesk (Turkey & Israel & Middle East & South Africa)

At Autodesk, Melike has been utilising her expertise to provide technical sales support, leveraging her extensive background to drive sales strategies and client engagement. Melike’s comprehensive approach and technical acumen have consistently contributed to enhanced client engagement and satisfaction, driving growth and efficiency in the organisations she has served.

Saihil Shivanand

Operations Director at Silver Solutions

Saihil Shivanand has been the Operations Director at Silver Solutions for 18 months, driving the company’s mission to deliver bespoke battery solutions. Saihil’s expertise comes from hands-on experience, including a course on Algorithms for Battery Management Systems and LiFePO4 cell diagnostic training. His early knowledge of lead acid technology aids in working with Lithium Phosphate, ensuring innovative and efficient battery solutions. Saihil emphasises creativity in design and problem-solving, both in production and after-sales service. He believes in thinking outside the box to solve daily challenges, leading Silver Solutions with a focus on innovation and excellence.

Henry Levine

CEO of Made in Workshop

Henry Levine is the CEO of Made In Workshop, a shared makerspace and fabrication studio based in Johannesburg. Driven by a passion for big machines and the ability to create, Henry founded the company to empower individuals and SMEs by providing access to essential tools and resources. Since January 2016, he has dedicated himself to teaching and learning from members, fostering a collaborative and innovative environment. With over 27 years of experience as the owner of Leonora Systems (Pty) Ltd, Henry has extensive expertise in managing printer contracts and MPS strategy development. His hands-on approach and commitment to helping others grow their businesses define his professional journey.