Webinar Overview

The “Future of Sustainable Manufacturing” webinar, hosted by Baker Baynes, provided a comprehensive exploration into sustainable practices in the manufacturing industry. The webinar featured insights from industry experts Michael Smith – Manufacturing Professional and Peter Watson – Autodesk Fusion Expert at Baker Baynes, who shared their extensive knowledge on sustainable manufacturing processes and the benefits of incorporating these practices into everyday operations. Attendees included professionals from various fields, such as engineering managers, CNC operators, and environmental engineers, all eager to learn how to make their manufacturing processes more sustainable and efficient.

Key Highlights

Introduction to Sustainable Manufacturing

Daniel Ballaram, Head of the Manufacturing and the Process Plant, Energy & Mining industry segment at Baker Baynes, began the webinar with an overview of the agenda and introduced the main speakers. He emphasised the importance of sustainable manufacturing, highlighting the growing trend among manufacturers to seek ways to reduce their environmental impact. This segment set the stage for the discussions that followed, focusing on practical strategies and tools for achieving sustainability.

Six Key Considerations for Sustainable Manufacturing

Peter Watson and Michael Smith outlined six critical areas for implementing sustainable manufacturing practices:

1. Waste Reduction: They discussed the importance of minimising waste through accurate simulation and programming, which prevents material loss due to errors or collisions during machining.

2. Energy Efficiency: Emphasising the significant energy consumption by CNC machines, they explored strategies to reduce energy use, such as optimising toolpaths and minimising non-running time.

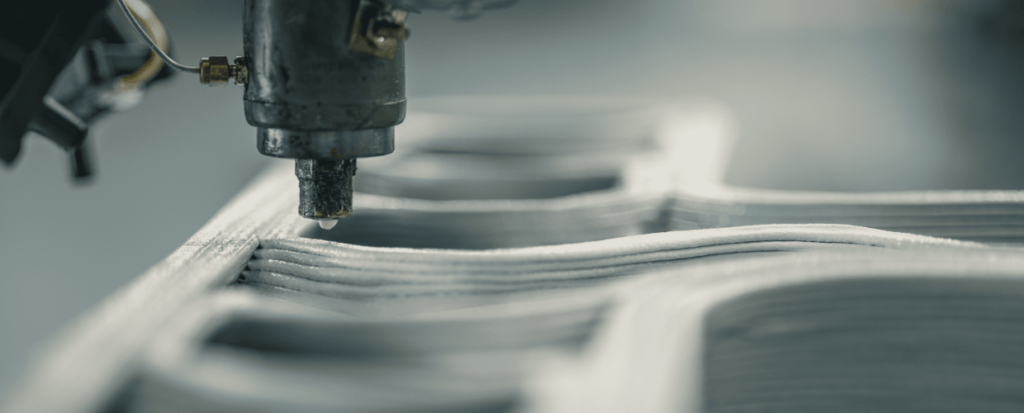

3. Coolant Strategies: The speakers reviewed different coolant strategies, including traditional flood cooling, dry cutting, minimum quantity lubrication (MQL), and cryogenic cooling, assessing their environmental and operational impacts.

4. Green Tooling: They highlighted the use of sustainable materials in tooling, such as carbide inserts and non-toxic coatings, which extend tool life and reduce environmental impact.

5. Sustainable Materials: The discussion covered selecting materials that are recyclable, recycled, or can be reused, emphasising the importance of choosing sustainable options in manufacturing.

6. High-Speed Machining: The benefits of high-speed machining techniques were discussed, including improved tool life, reduced machining time, and increased energy efficiency.

Key Outcomes

Practical Steps for Implementation

The session offered practical steps for integrating sustainability into manufacturing processes. This included adopting green tooling, optimising energy use, and using sustainable materials, all of which can lead to significant cost savings and improved environmental outcomes.

Enhanced Understanding of Sustainable Practices

Attendees gained a deeper understanding of sustainable manufacturing practices, including the latest tools and technologies available to support these initiatives. The webinar provided actionable insights on how to reduce carbon footprints and enhance operational efficiency.

Digital Transformation for Improved Efficiency

The speakers emphasised the role of digital tools, such as Autodesk Fusion, in transforming workshop operations. These tools enable better planning, simulation, and execution of manufacturing processes, leading to increased efficiency and sustainability.

Detailed Insights from the Webinar

Waste Reduction Strategies

Michael Smith demonstrated the impact of accurate simulation and programming on waste reduction. He illustrated how programming errors, machine collisions, and tool collisions can lead to significant material loss and increased costs. By using advanced simulation tools like Autodesk Fusion, manufacturers can predict and prevent these issues, ensuring optimal material use and reducing waste.

Energy Efficiency Measures

The speakers highlighted the importance of minimizing machine idle time and optimizing toolpaths to reduce energy consumption. They explained how auxiliary components of CNC machines, such as coolant pumps and chip conveyors, contribute significantly to energy use. By focusing on efficient toolpath design and reducing non-productive time, manufacturers can lower their energy bills and reduce their environmental impact.

Coolant Strategies and Their Environmental Impact

Peter Watson discussed the environmental and health impacts of different coolant strategies. Traditional flood cooling is effective but can be wasteful and environmentally harmful if not disposed of correctly. Alternative methods like MQL and cryogenic cooling offer more sustainable options, reducing the amount of coolant used and minimising the risk of environmental contamination.

Green Tooling and Sustainable Materials

The webinar emphasised the importance of selecting sustainable materials and tooling options. Green tooling, such as carbide inserts and tools with non-toxic coatings, not only reduce environmental impact but also enhance tool life and machining efficiency. Additionally, using sustainable materials, such as recycled metals or bioplastics, helps conserve natural resources and reduce the carbon footprint of manufacturing operations.

High-Speed Machining Techniques

High-speed machining was presented as a key technique for improving efficiency and sustainability. This method involves using high speeds and feeds to maximise material removal rates while minimising heat generation and tool wear. The result is faster machining times, lower energy consumption, and improved tool longevity, making it an essential strategy for sustainable manufacturing.

Conclusion

The “Future of Sustainable Manufacturing” webinar provided valuable insights into how manufacturers can adopt more sustainable practices. By focusing on waste reduction, energy efficiency, sustainable materials, and advanced machining techniques, manufacturers can significantly reduce their environmental impact while also improving operational efficiency and cost-effectiveness. The webinar highlighted the role of digital tools like Autodesk Fusion in facilitating these changes, offering a path forward for companies looking to enhance their sustainability practices.

For more information and resources, attendees were encouraged to download the Baker Baynes ebook and explore the full range of transformation tools available on their website. The webinar concluded with a call to action, urging participants to take proactive steps towards sustainable manufacturing and to reach out for support in implementing these strategies.

About the Presenters:

• Michael Smith: A seasoned manufacturing professional with a background in furniture and CNC manufacturing, Michael Smith brings a wealth of experience to his role at Baker Baynes. With expertise in CNC post processors and a passion for sustainable manufacturing, he is a key advocate for integrating advanced technologies into manufacturing processes.

• Peter Watson: As an Autodesk Fusion expert at Baker Baynes, Peter Watson focuses on the intersection of CAD/CAM and manufacturing technology. His work emphasizes improving efficiencies and productivity in manufacturing, leveraging his deep understanding of CAD/CAM integration to streamline processes and enhance operational outcomes.

0 Comments